So, we decided to take a break from chronicling our move to California to start our home brew diary! So if you are reading this and wondering how we are brewing on the road, well, we are not. The chronicles of our westward journey are being provided after the fact. We arrived at our rental in Davis, CA on January 20, 2016. Perhaps we should have altered you, gentle reader, that this paragraph contained spoilers. Ah well. Check out our travel posts. At the minimum, there are some pretty pictures.

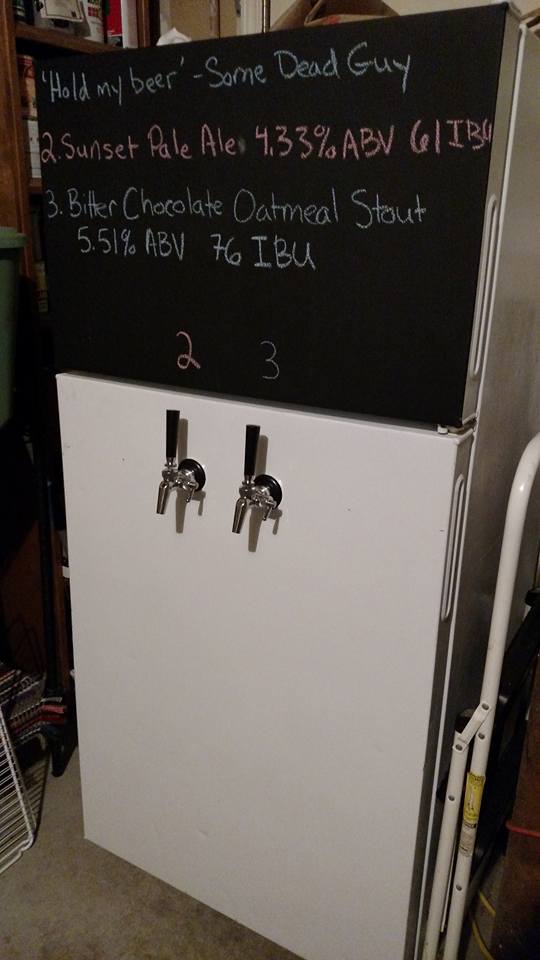

On our travels, we just happened to pass by Concord, CA, home of a More Beer! retail store. Of course we stopped. And bought two all grain kits: Sunset Pale Ale (#583) and Stone’s Bitter Chocolate Oatmeal Stout (#800). The goal was to brew the beautiful weekend of January 23rd, but common sense prevailed. We decided to postpone until we got better settled into our new home and Dave reassembled the brew equipment.

What went right

- Strike water temperature to achieve the correct mash. Jess took the time to calculate the heat input required to raise the malt to mashing temperature (Q=m*Cp*(T2-T1); where Cp of the mash is estimated at 1680 J/kg*Celsius). This heat input was then used to calculate the temperature the strike water needed to be heated to in order to achieve the desired temperature at mash in.

- Alex enjoyed tasting the malted barley and helping wash and sanitize the hoses. As long what is being cleaned isn’t Alex’s face or hands, he is all for it. He was a good brewer’s assistant. Never fear, once the propane burners were lit, he was safely inside.

What went wrong

- The weather. A cooler day, the constant breeze illustrated the powers of convection. Throw in the fact that the wind blew out our burners a couple of times, it is no wonder it took so long to heat our liquids.

- Shaking the dust off. It was series of little things because we haven’t brewed in a couple of months. Finding the proper hose with the right couplings, a kettle that was leaking due to the gaskets, remembering that the pump needed to be primed. Those small things add up to some serious lost time.

- Chocolate nibs are an impressive clogging agent, especially coupled with a plate chiller. This only emphasizes how our process needs to be refined. We will get there. Nothing a little whirlpool action and some filtration won’t solve.

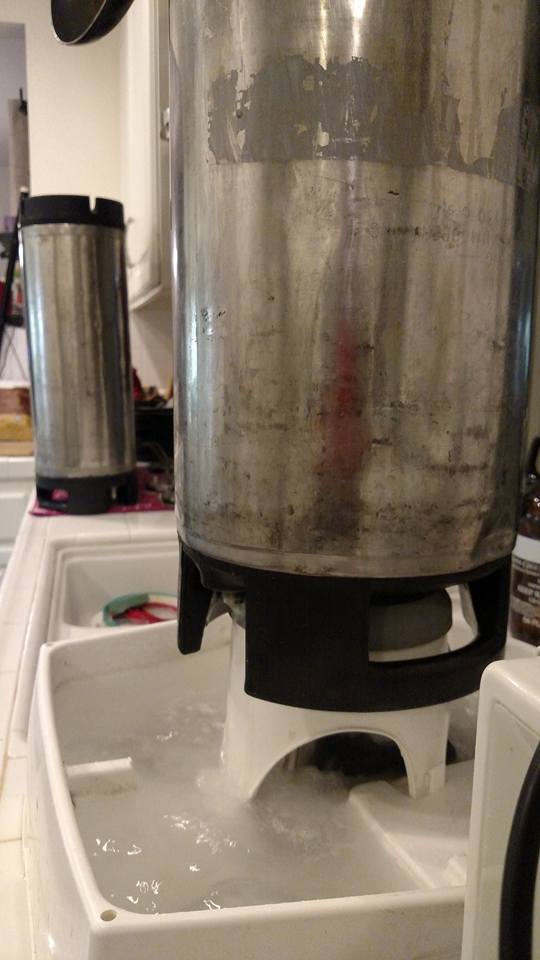

- The amount of water we needed to use to chill our wort. We definitely need to improve our water conservation. Or hide our usage from our neighbor. The target is conservation.

Sunset Pale Ale Recipe and Stats

Grain Bill: 8 lbs American Pale, 2 lbs Munich, 0.5 lbs Carastan, 0.5 lbs Carapils

Hops (Pellets): 1 oz Amarillo 8.5% AA 60′, 0.5 oz Northern Brewer 7.0% AA 30′, 0.5 oz Cascade 5.5% AA 10′, 1 oz Amarillo 8.5% AA 5′, 1 oz Tettnanger 4.6% AA dry hop

Yeast: White Labs Pure Pitch WLP001 California Ale

Original Gravity: 1.059

Final Gravity: TBD

Fermentation Temp: 20 Celsius

Observations:

- Fermentation started by Monday morning.

Stone’s Bitter Chocolate Oatmeal Stout

Grain Bill: 15 lbs Two Row, 2 lbs Flaked Oats, 1.5 lbs Pale Chocolate Malt, 1 lb Black Patent, 1 lb Roasted Barley, 1 lb Crystal 15 L, 8 oz Carapils

Hops (Pellets): 4 oz Willamette

Additions: 4 oz Cacao Nibs added with 15′ left in boil

Yeast: White Labs PurePitch WLP001 California Ale

Original Gravity: 1.090

Final Gravity: TBD

Fermentation Temp: 20 Celsius

Observations:

- After mash was finished, the air bubbles on top of the grain bed were multi-colored which is indicative of a good mash.

- A lot of trub at end. Clogged the plate chiller pretty quickly.

- This is going to be a dark, dark beer.

- Fermentation was going around midday Monday.